Next-Generation Rebar Alternative: GFRP

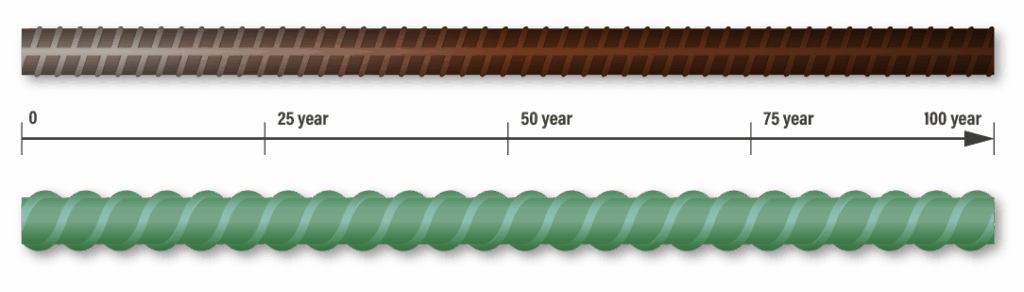

Steel vs GFRP Service Life Comparison

Category

Steel Rebar

GFRP Rebar

1. Service life in normal environments

(with proper maintenance)

Steel Rebar

50 – 100 years

GFRP Rebar

Over 100 years

2. Service Life in Harsh Environments

(marine / high-salinity areas)

Steel Rebar

20 – 40 years

GFRP Rebar

Over 100 years

3. Main Cause of Reduced Service Life

Steel Rebar

Corrosion and crack

GFRP Rebar

None

Four Key Advantages of GFRP Rebar

25 %

0 %

30 %

100 Y

Productivity & Workability

Lightweight

About one-fourth the weight of steel rebar, making handling and transport much easier.

Faster Installation

Reduces installation time by up to 30%.

Safety

Superior Corrosion Resistance

Does not rust even when exposed to water, salts, or chemicals, completely preventing rebar corrosion problems.

Extended Service Life

Extends the lifespan of structures in corrosive environments by over 100 years.

Environmental Sustainability

Low Carbon & Energy Footprint

Requires less energy during production than steel and produces far lower CO2 emissions.

Sustainable Infrastructure

Longer structural lifespan reduces material waste and resource consumption.

Cost Efficiency

Reduced Life-Cycle Cost (LCC)

Minimizes long-term maintenance expenses due to excellent corrosion resistance

Low Maintenance Requirement

Corrosion resistance significantly cuts repair and upkeep costs.

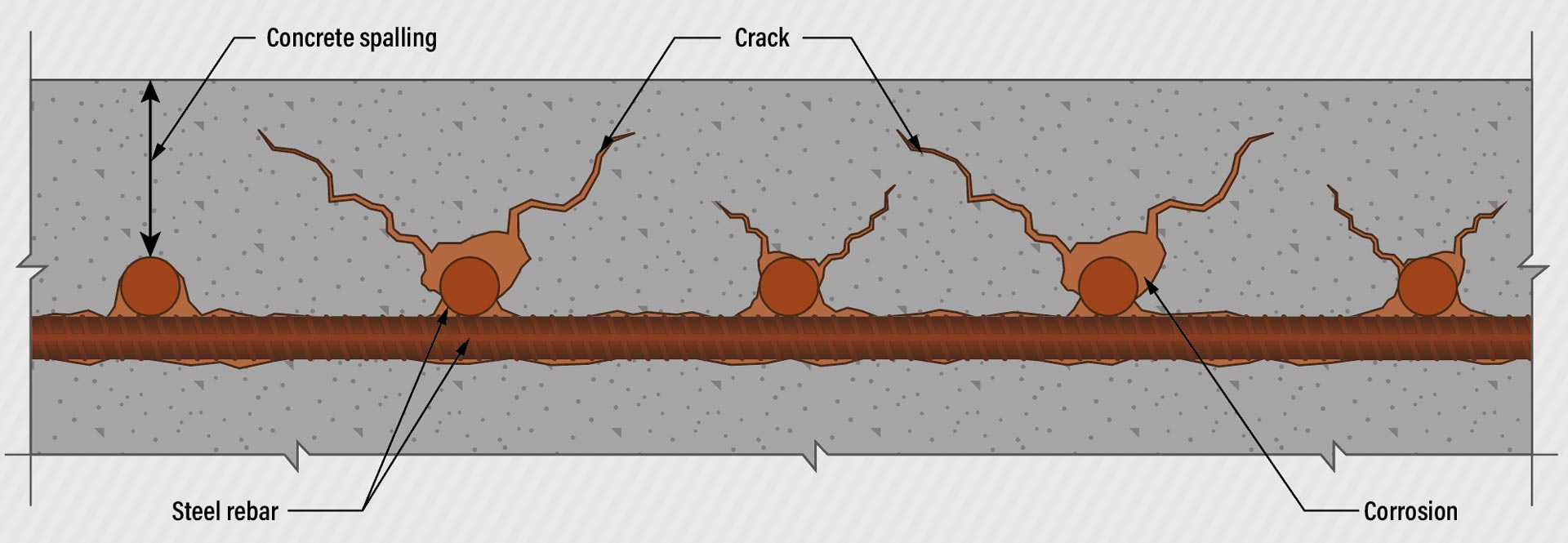

As steel corrodes, the rust that forms expands in volume, creating internal tensile stress within the concrete.

This stress leads to cracking, spalling, and delamination. A phenomenon known as concrete deterioration due to corrosion.

To build safer, longer-lasting, and more sustainable concrete structures, GFRP Rebar is being rapidly adopted across a wide range of applications, establishing itself as the new standard for future infrastructure.